CAP1400 reactor vessel passes pressure tests

Hydraulic pressure testing has been completed on the reactor pressure vessel for the demonstration CAP1400 unit to be built at Shidaowan in China's Shandong province.

The vessel - with a total weight of about 487 tonnes - underwent a two-stage hydraulic pressure test to confirm the integrity of its welds and seals. The tests were witnessed by officials from China's regulator, the National Nuclear Safety Administration; reactor designer, the Shanghai Nuclear Engineering Research and Design Institute (SNERDI); and the manufacturer of the vessel, China First Heavy Machinery Group.

The first stage of the tests involved raising the pressure within the vessel to 21.5 megapascals (MPa) and maintaining it at that pressure for 10 minutes to check the integrity of the vessel. The pressure was then lowered to 17.2 MPa - the design pressure for the vessel - and the O-ring seals were then checked for leaks both internally and externally. The tests were successfully completed on 17 March.

The China Advanced Passive Pressurized Water Reactor (CAP1400) is one of the serial research and development of PWRs adopting passive engineered safety features initiated by SNERDI. The design of CAP1400 is based on the experience of the PWR tehnology R&D for more than 48 years, construction and safe operation for more than 25 years in China. As one of China's 16 strategic projects under its National Science and Technology Development Plan, the CAP1400 is intended to be deployed in large numbers across the country.

In May 2016, the CAP1400 design successfully passed the International Atomic Energy Agency's Generic Reactor Safety Review. This review is not a clearance process but a review of the quality of the safety documents identifying strengths, weaknesses and gaps.

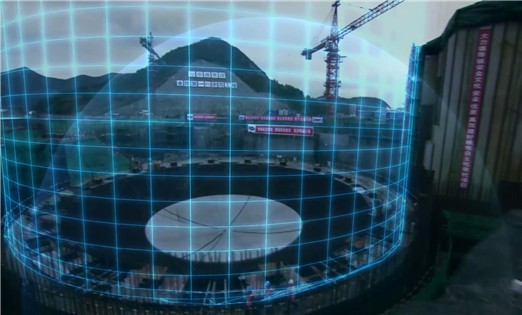

Site preparation is already underway for two demonstration CAP1400 units at Huaneng Group's Shidaowan site in Shandong province.